Focusing on the application requirements in the subdivided field, Xianlin 3D assisted Wuhan Biying Biotechnology Co., Ltd. to build the world's first orthopedic external fixation 3D real-time printing system that meets the requirements of clinical operation specifications with excellent high-precision 3D scanning technology.

Through the combination of the advantages of the products of both sides, it aims to better serve more hospitals, institutions or enterprises that specially customize external fixations, orthopedics and other rehabilitation aids products for orthopedic patients, and bring new assistance to the public health.

The manufacturing speed of orthopedic 3D printing external fixator doubled

It is well known that the traditional orthopedic external fixation technology uses plaster to help the reduction, but the efficiency of plaster is too low and inaccurate, and the patients are not easy to remove and wash. Therefore, the "3D printing external fixator" technology, which can easily help patients to accurately reposition, reduce patients' pain and promote fracture healing, has been applied more and more in recent years.

However, the manufacturing process of general 3D printing external fixed support has obvious disadvantages, such as:

The patient needs to be fixed within 2 hours after injury, otherwise it will easily lead to secondary injury, and the common 3D printer is difficult to meet this requirement, and the design and printing time will add up to more than 5-7 hours.

The process of mold taking, design and production is tedious. Most doctors do not have relevant professional software and machine operation knowledge, and the learning threshold and time cost are high.

To this end, BIYING Biotechnology has created a real-time 3D printing external fixation system, an automatic system that can obtain body surface data through handheld scanning equipment, and use composite starch-based powder materials to instantly construct external fixation supports through layer-by-layer printing based on digital model files.

For example, the production of external fixation brace of wrist joint:

Scan the wrist with a handheld 3D scanner, and the wrist model can be automatically drawn on the computer within 20 seconds;

The model data can be printed out with 3D printer after being processed, designed and sliced by the system intelligently;

The efficiency is more than 20 times that of the traditional 3D printing external holder technology.

From 7 hours to 20 minutes, the real-time 3D printing external fixation system doubled the manufacturing speed of orthopedic 3D printing external fixation frame.

High-precision 3D digitization technology

Booster of precision customization of medical accessory industry

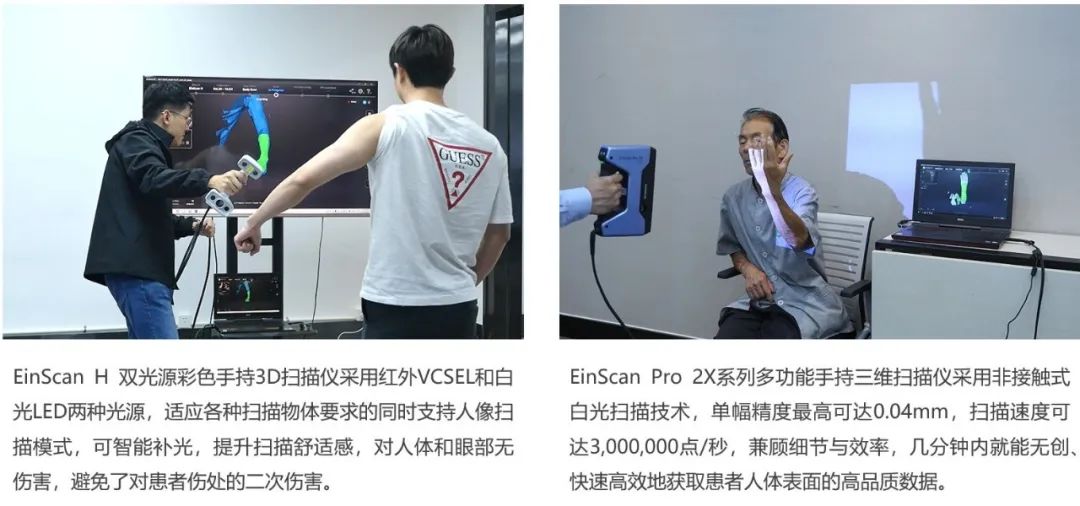

In the process of system research and development, in order to improve the working process and improve the overall production efficiency and quality, the research and development team of BIYING Biotechnology finally chose to cooperate with Xianlin 3D after a number of comparative tests, and included the EinScan Pro 2X series multi-functional handheld 3D scanner and EinScan H dual-light color handheld 3D scanner into the "data acquisition" link of the real-time 3D printing external fixation system.

Advantages of real-time 3D external fixed printing system

It can take 2-3 minutes to quickly complete the digital mold taking, obtain accurate data, and then achieve the best recovery posture through the system intelligent design to perfectly fit the affected part;

High degree of automatic processing, instant printing and molding, patient disposal can be completed within 20-30 minutes, meeting the requirements of clinical specifications;

The brace is made of porous design, light and breathable, which can effectively avoid the wounds of patients, not affect the dressing change and wound treatment, and improve the healing rate;

Less clinical contraindications, accurate reduction and firm support can promote fracture healing, reduce postoperative recovery time and relieve patients' pain;

Compared with traditional petroleum-based materials, all-starch materials are more eco-friendly, with low price, and greatly improved aesthetics, hardness, and body feel.

Through this cooperation combining technical characteristics, Xianlin 3D and Biying Biotechnology will work together to promote the application of 3D scanning and 3D printing technology in orthopedic external fixation, orthopedic appliances and other medical rehabilitation appliances and other fields, and help the medical rehabilitation aids industry with a hundred billion market to develop towards digitalization, personalization, precision and intelligence.

In the future, Xianlin 3D will continue to explore more segmentation scenarios in the medical industry, provide high-quality and efficient 3D digital products and services for customers around the world, and deepen the application of high-precision 3D digital technology in the field of precision medicine, so as to help create a healthier quality life with the power of science and technology!

|

Prev:None!

Next:None! |

Return |