On June 27, 2022, the Antarctic Bear learned that the US start-up Syntris had raised US $2.7 million to develop a new ceramic 3D printing method.

△ Company corner

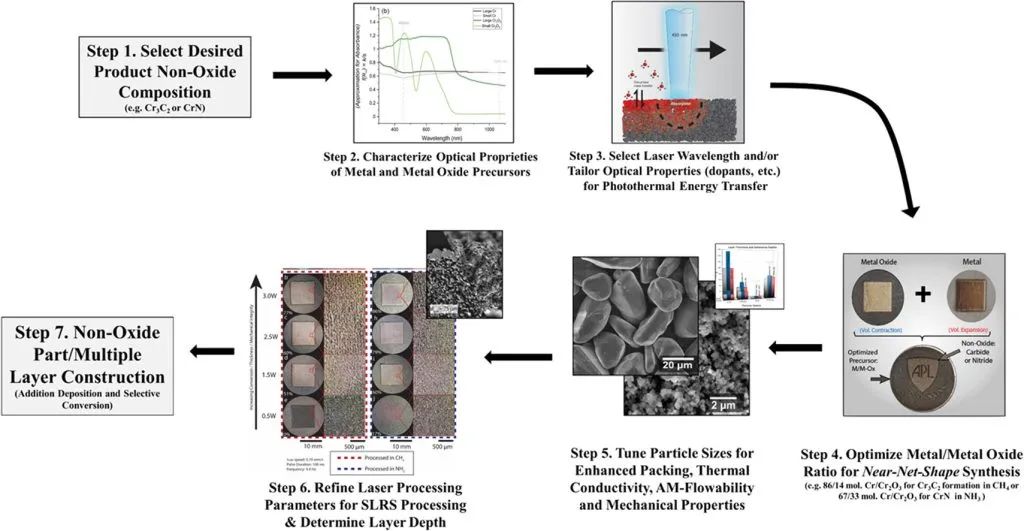

This technology is called Selective Laser Reactive Sintering (SLRS), which aims to be an alternative method of producing parts with non-oxide ceramics (such as carbides, nitrides and borides). ARPA-E is very optimistic about this new technology, so it funded it. Now, the company's primary goal is to build a SLRS ceramic 3D printer to realize a new electronic package that can improve the performance of electric vehicles and aircraft.

Selective Laser Reactive Sintering (SLRS)

As one of the nine subsidiaries of Early Charm Ventures, Syntris' business mainly comes from the new technology developed by the Chief Technology Officer Adam Peters in the physics laboratory. Although they have not officially disclosed their patented technology, according to the Antarctic Bear, it uses the reaction between the laser-induced reaction precursor and the gaseous atmosphere to synthesize carbides or nitrides.

Unlike ordinary ceramic 3D printing, Syntris' technology aims to achieve in situ manufacturing of ceramics, rather than direct laser melting of materials. According to Peters, using chemical reaction to produce ceramics can overcome the requirements of fragility and high temperature when 3D printing ceramics in the past.

Researchers from Johns Hopkins University have tried to use this technology to develop near-net 3D printing ceramics, which can produce components with sub-millimeter spatial resolution and certain thickness.

At the beginning of 2016, Peters and his team have been developing 3D printing with high-temperature ceramics such as silicon and zirconium carbide since the Navy Research Office received research and development funds. He applied for a patent in 2019 and commercialized it through the foundation of Syntris the next year.

△ Example SLRS process

Supported by ARPA-E

The latest funding Syntris received from the US government is part of the US $175 million plan of the Department of Energy, which aims to address the new challenges of green energy in the US. At the same time, it has also been selected as one of the 68 projects supported by Open 2021, covering all aspects from offshore wind power to nuclear recovery, and is expected to promote energy security and employment in the United States in these areas.

Recently, Syntris intends to deploy this technology into 3D printing ceramic packaging of power electronics modules, which are widely used to transfer energy from batteries to motors. Specifically, they plan to test the feasibility of ceramic technology through experimental equipment, which is very high for start-ups.

"The equipment we need is about $500000 each, which is not an easy thing, so I think it will open the door to new technology. If you can print unique geometric shapes in 3D, you can carry out more efficient energy transmission, so as to obtain better performance and efficiency."

The geometry of the 3D printing module can promote greater heat transfer, resulting in better efficiency and durability. He added: "The funding from ARPA-E is enough to prove the future development prospects of our technology."

△ Adam Peter, chief technology officer of Syntris

Commercialize ceramic 3D printing

Although ceramic 3D printing needs to be fully optimized in some cases, it has shown that it can be used as a potential means to solve end-use and green energy applications.

At the beginning of 2021, XJet delivered the first Carmel 1400M 3D printer to Azoth. The system uses nanoparticle jet metal and ceramic printing technology, which has great potential in the biomedical field.

HRL Laboratory, the research and development center of General Motors and Boeing, has also made progress in this field and developed a new method of 3D printing ceramic matrix composites. The company said that its new technology could be used to manufacture glass materials with propulsion, energy and chemical processing applications.

|

Prev:None!

Next:None! |

Return |