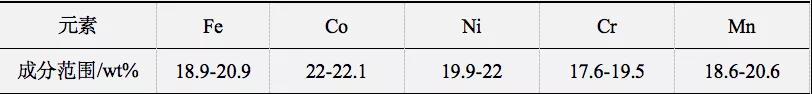

High-entropy alloy is composed of more than 5 (generally no more than 13) major elements (metal or metal and non-metal), and the atomic fraction of each major element shall be greater than 5% and no more than 35%. FeCoNiCrMn high entropy alloy was used in the experiment. Its theoretical atomic ratio is 1 ∶ 1 ∶ 1 ∶ 1 ∶ 1, and the mass fraction range is shown in Table 1.

Table 1 Composition of FeCoNiCrMn

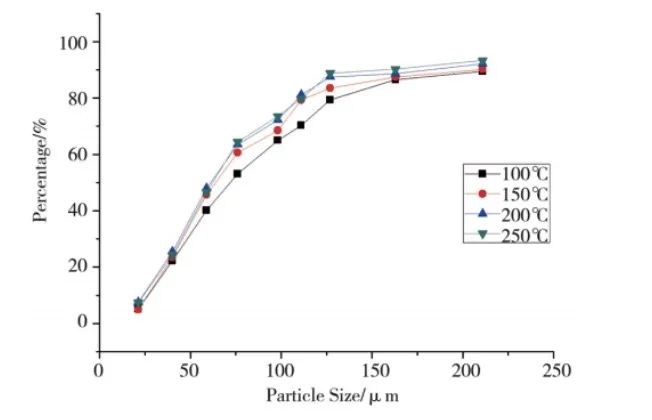

The particle size data is displayed as a percentage of volume accumulation, for example, the test result is Dv (50)=100 μ m. That is, the particle size is less than or equal to 100 μ M powder accounts for 50% of the total sample. Because the sphericity of the aerosol powder is very good and the number of hollow spheres is very small, the particle size value corresponding to the sample Dv (50) can be regarded as the median particle size of the sample.

Fig. 1 Powder accumulation curve under different superheat

In order to study the effect of superheat on the particle size of powder, atomization was carried out at 100 ℃, 150 ℃, 200 ℃ and 250 ℃, respectively, with the atomization pressure controlled at 5.0MPa and the insulation temperature controlled at 1100 ℃. The atomized powder is screened by 50 meshes and mixed evenly, and its particle size is tested. The test results are shown in Figure 1.

According to the experimental data, when the superheat is 100 ℃, Dv (50)=71.4 μ m; When the superheat is 150 ℃, Dv (50)=68.9 μ m; When the superheat is 200 ℃, Dv (50)=65.6 μ m; When the superheat is 250 ℃, Dv (50)=65.5 μ m。 It can be seen that when the superheat of the alloy liquid increases, the median particle size Dv_ (50) decreases; When the superheat reaches 200 ℃, the influence of the increase of superheat on the particle size of the powder becomes smaller. The process of gas atomizing alloy liquid is usually divided into three stages: primary crushing, secondary crushing and cooling solidification. After contacting the atomized gas, the alloy liquid is first pulled into a liquid film, then the liquid film is broken into small droplets, and finally the droplets are cooled into solid powder. The final particle size of the powder is mainly determined by the state of secondary crushing.

If the superheat of the alloy liquid is low, it will solidify after its initial crushing, and will not be further broken into smaller particles by the gas in the secondary crushing stage, so the particle size of the powder is relatively large. At the same time, when the degree of superheat is lower than 100 ℃, because the atomization uses normal temperature and high pressure gas, it enters the relatively open atomization barrel after being sprayed out through the narrow nozzle of the atomizer, and the gas expands rapidly while participating in the atomization, and a large amount of heat absorption will lead to the rapid cooling of the nozzle restricting the alloy liquid. Due to the small inner diameter of the nozzle, the alloy liquid inside will solidify directly due to the slow flow rate, resulting in the suspension of the atomization process. When the degree of superheat increases from 100 ℃ to 200 ℃, the powder solidified at the time of initial crushing will decrease, and the proportion of powder that can be broken for the second time will increase, so the powder particle size will decrease. When the degree of superheat exceeds 200 ℃, the number of droplets solidified after the initial crushing has dropped to a sufficiently low level, and most of the droplets will participate in the secondary crushing process. Further increase of superheat will no longer significantly increase its proportion. Therefore, when the superheat exceeds 200 ℃, the particle size of the powder will not change significantly with the increase of temperature.

When FeCoNiCrMn high entropy alloy is prepared by atomization method, the atomization state of the alloy liquid can be changed by changing the superheat degree under the condition that the atomization pressure and holding temperature are constant. The higher the superheat, the finer the particle size of the powder. When the superheat exceeds 200 ℃, the influence of superheat on the particle size of the powder is greatly reduced.

|

Prev:None!

Next:None! |

Return |