On June 28, 2022, the Antarctic Bear found on the kickstarter crowdfunding platform that the top five global crowdfunding 3D printer projects with the highest amount of money were all from Chinese manufacturers, of which the AnkerMake M5 3D printer project of Anker Innovation Company (Anker) raised the highest amount of money - up to 8.88 million US dollars (nearly 60 million yuan), which also further shows the absolute advantage of domestic desktop 3D printers worldwide.

(Special tip from Antarctic Bear: The sales volume of 3D printers on crowdfunding platforms is only part of the total sales volume of manufacturers. More products are sold through e-commerce and other channels.)

It is worth noting that the five leading manufacturers are all from Shenzhen, China. As an important additive manufacturing industry cluster in China, Shenzhen has initially formed an industrial ecosystem covering the entire chain of materials, devices, software, equipment and application services, with rich manufacturing application scenarios, and also provided broad market space and opportunities for the innovative drive and industrial development of 3D printing technologies such as desktop-level melt deposition modeling (FDM). In this article, the Antarctic Bear introduces these five domestic 3D printers that are famous overseas in turn, summarizes their respective functional characteristics and detailed information of manufacturers, so that readers can have a more systematic understanding of domestic desktop 3D printers.

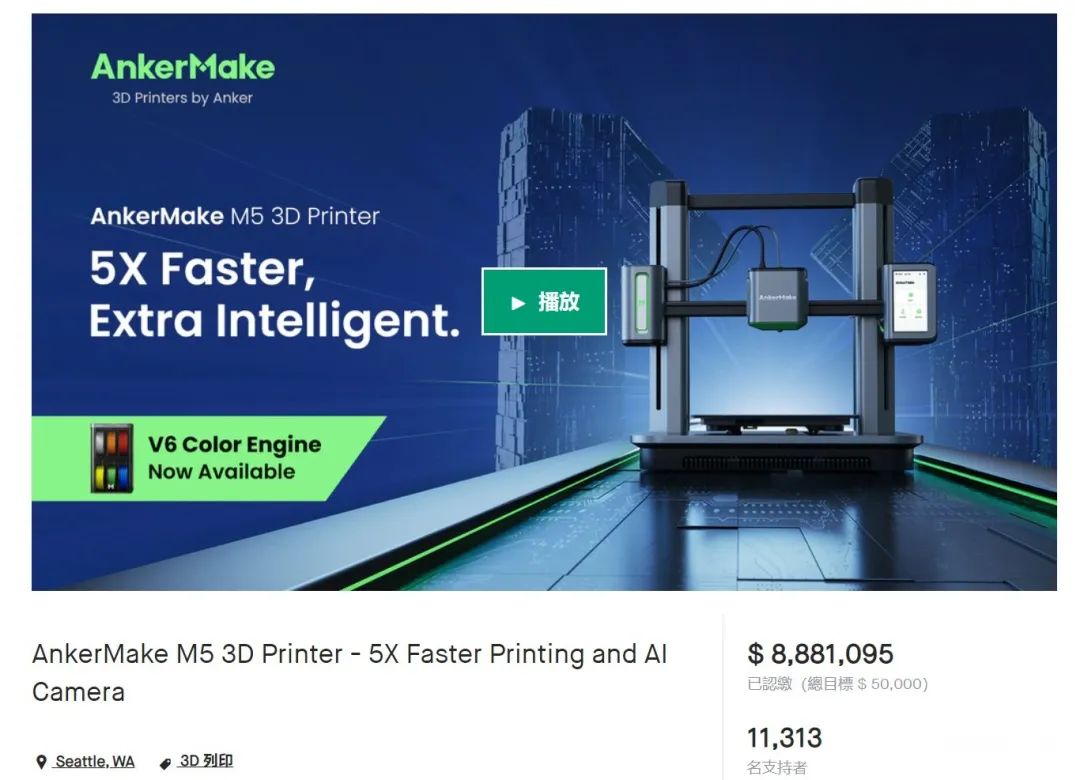

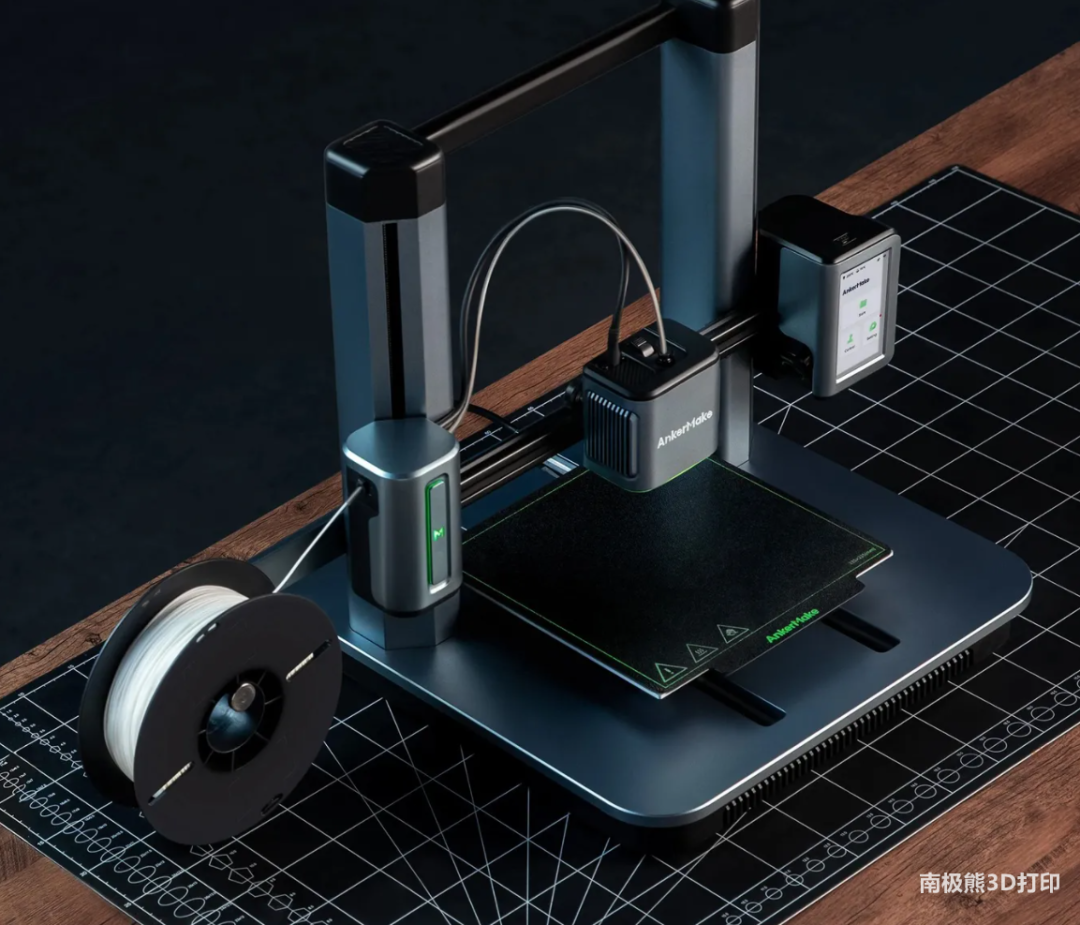

First place: AnkerMake M5

Crowdfunding: $8881095 (about 59.37 million yuan)

Number of supporters: 11313

As a global high-quality intelligent charging expert, Shenzhen Anker has always been famous for charging products. Now the company has expanded from Eufy smart home equipment, Soundcore audio, Nebula projector and Roav auto accessories to 3D printing. Anker announced that the newly developed 3D printer AnkerMakeM5 will be launched in September 2022. It is said that it can solve many problems existing in the current market of 3D printers, such as speed and long preparation time before printing, which may cause a strong impact on the current consumer 3D printer market.

AnkerMake M5 is an extrusion 3D printer with a printing speed of 250mm/s. If customers need high-precision products, they can use this speed. The AnkerMake M5 printer is also equipped with a faster mode, with an acceleration of up to 2500 mm/s. However, this will be at the expense of precision. The final part obtained is not of high precision and has fewer manufacturing details. This mode is mainly applicable to prototype manufacturing and toy printing. Anker said that the average print time of M5 was reduced by 70% compared with other printers.

Another feature of M5 is that the preparation time before printing is very short. It obviously takes only 15 minutes to prepare for printing. In addition, unlike other 3D printers, AnkerMake does not need people to be around, and can use the built-in AI camera to monitor print jobs. If it detects problems such as nozzle blockage, it can send an alarm to the user. No matter where the user is, you can view the real-time information of the print job through the corresponding app of Anke, which allows you to watch the print remotely, record the delayed video of your creation, and automatically pause the print job.

△AnkerMake

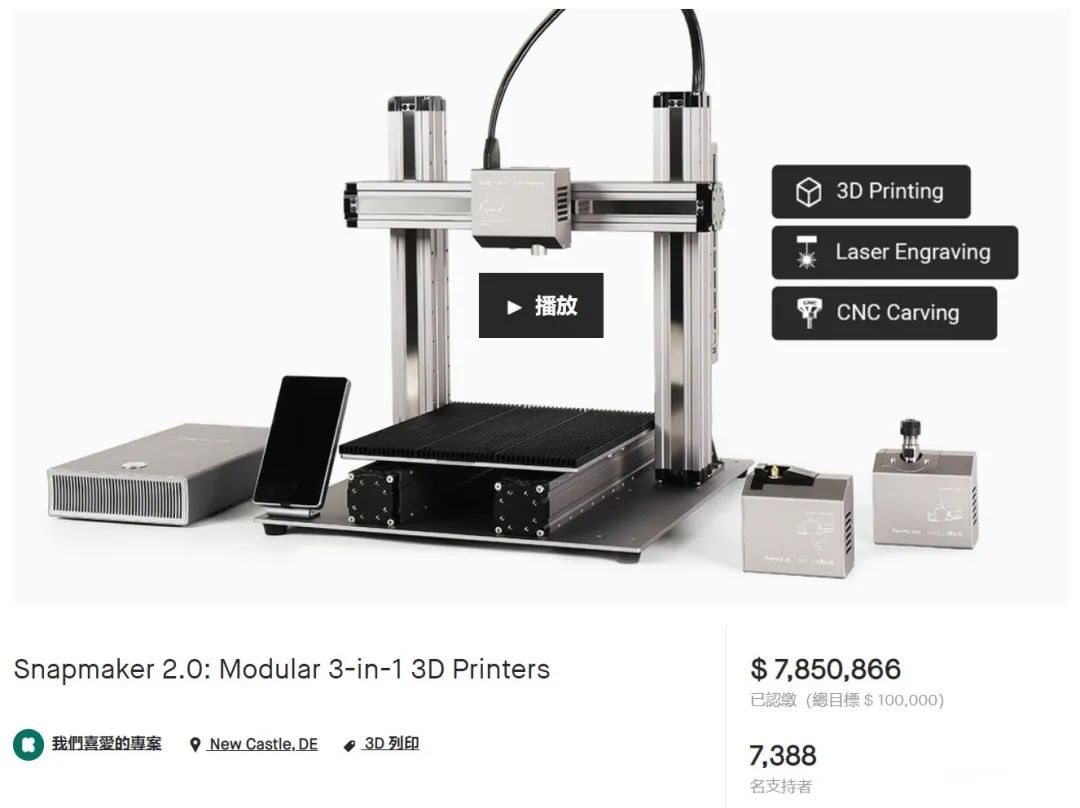

Second place: Fast Manufacturing Technology-Snapmaker 2.0

Crowdfunding: $7850866 (about RMB 52.48 million)

Number of supporters: 7388

Shenzhen Snapmaker Technology Co., Ltd., founded in 2016, is one of the most innovative digital manufacturing tool startups in China. Starting from digital manufacturing, the company combines additive manufacturing and subtractive manufacturing, and develops ingenious three in one modular desktop manufacturing tools, integrating three technologies of 3D printing, laser engraving and cutting, and CNC engraving. As an extraordinary 3D printer R&D company, its corporate philosophy and product connotation have brought new ideas to the additive manufacturing industry and led the multi-dimensional thinking of 3D printing additive manufacturing. In 2021, Jingwei China will lead the investment, and Tongchuang Weiye will follow the A-round of tens of millions of financing, and the company will enter a new track.

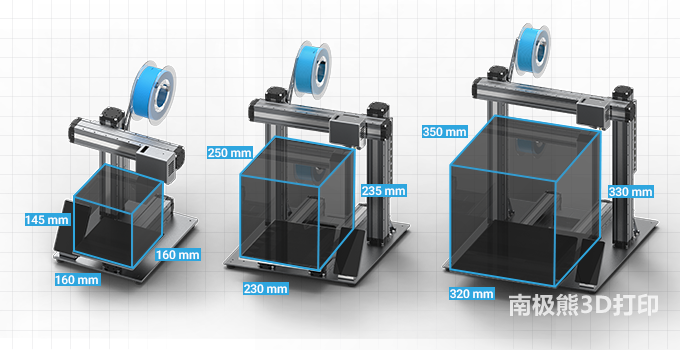

△ Three models of Snapmaker 2.0 F. Photo from Snapmaker.

Snapmaker 2.0 modular three-in-one 3D printer is very suitable for beginners, fans of customized products, and engineers and designers who want to print large objects or precise parts with excellent print quality. Snapmaker 2.0 has three models: A150, A250 and A350. It can make large prototypes or multiple smaller objects at one time. The maximum construction volume provided by A350 is 320 x 350 x 330 mm. Specifically, this innovative model has the following technical features:

Multi function: Snapmaker 2.0 products are characterized by three in one, modularization and high quality. Users can switch between different functions through quick disassembly and installation, and can continuously upgrade and customize. For creative people, multiple powerful modules and various expansion components can be used to form another system. When modular components are damaged, they can also be quickly positioned and replaced, saving more maintenance time;

Wide processing range: In print mode, Snapmaker 2.0 can print almost any object from ordinary parts to specific mechanical properties (such as toughness, durability and flexibility). In the carving/cutting mode, paper, plywood, leather, acrylic acid, cardboard, paper, fabric, and even biscuits and coconuts can be processed;

Good durability: All models of Snapmaker have good durability. Snapmaker 2.0 further breaks through the boundary of all-metal structure, and all modules and main components are made of high-strength metal. For example, the controller board and power adapter use aluminum alloy housing to better heat dissipation. The original POM roller is upgraded to steel roller to provide higher bearing capacity and stiffness;

High resolution: Snapmaker 2.0 uses high-precision parts and overall upgrade design, and can consistently print, carve, cut and carve objects with high resolution. The repeatability of the machine is 0.005 mm, and the return repeatability is 0.01 mm;

Convenient operation: Snapmaker js, a 3-in-1 software tailored for Snapmaker 2.0, has very powerful functions and has undergone many iterations and upgrades. The device can also be connected to any configuration via Wi-Fi function and USB port for easy use;

Automatic recovery: Snapmaker 2.0 can automatically detect power failure, and then recover from the location of the interruption. There is no need to worry about accidental power failure. The operator can recover any item and always obtain perfect printing/engraving/cutting/engraving results.

Now, Snapmaker has initially completed the expansion and construction of the product ecosystem, taking Snapmaker 2.0 three-in-one 3D printer as the core, and then launching modules and expansion components such as the cover, air purifier, rotating module, 10W high-power laser module, emergency stop switch and docking station, providing consumers with safe, reliable, professional and smooth consumer-level creative experience in all aspects.

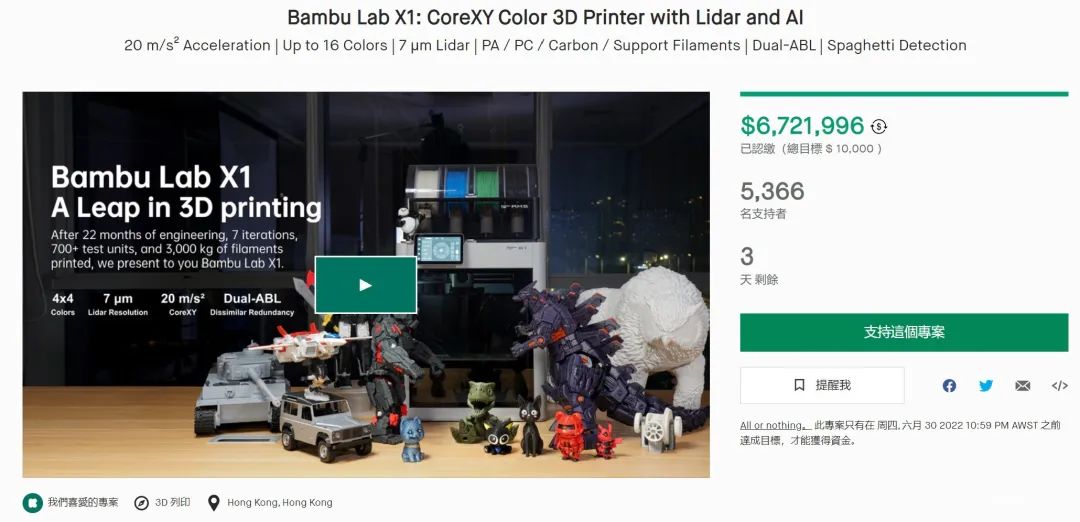

Third place: Tuozhu Technology-BambuLab X1

Crowdfunding: $6721996 (about RMB 44.94 million)

Number of supporters: 5366

△ End crowdfunding with the last day or two left

Shenzhen Tuozhu Technology Co., Ltd., founded in 2020, is a new start-up company founded by a group of 3D printer enthusiasts with deep research and development background. The team has top experts in mechanical/mechanical design, motion control, machine vision, artificial intelligence, computational mechanics, embedded software, cloud computing and other fields.

The high-speed multi-color 3D printer of Bambu Lab X1 released by Tuozhu Technology has many core highlights:

High-performance materials: support carbon fiber reinforced nylon, polycarbonate and other high-temperature resistant and high-strength materials that used to be limited to industrial products

Multi-color and multi-material: support up to 16 color 3D printing, and the rich color and material matrix make 3D printing farewell to the black-and-white era

Ultra-high speed printing: 20000 mm/s2 acceleration and 500 mm/s printing speed, an order of magnitude higher than the current industry standard

Built-in laser radar: equipped with a micro-laser radar with a resolution of up to 7 microns to realize high-precision closed-loop printing process

Support material: use easy-to-peel or soluble support material to solve the support stripping problem that has troubled 3D printing for many years

Energy conservation and environmental protection: reduce carbon emissions by 80% and plastic waste by 20%

Artificial intelligence: 43 sensors covered with the fuselage cooperate with the NPU of the main chip to realize automatic double redundant leveling, extrusion compensation, vibration suppression, component self-test and other automatic functions

Fourth place: Intelligence-ElegooJupiter

Crowdfunding: $4740248 (about RMB 31.69 million)

Number of supporters: 5118

Shenzhen Elego Technology Co., Ltd. (Elego), established in Shenzhen, China in 2015, is an award-winning technology brand dedicated to providing customers with highly functional and cost-effective 3D printing solutions. From 3D printers and programs to basic accessories, such as resins, cleaning and curing machines, and Arduino software, Elego focuses on providing customers with high-quality products and unparalleled customer service.

In the past six years, Elego has expanded to the world, and its products have been used in the United States, Canada, Mexico, Germany, France, Italy, Spain, Japan, India, Australia, the United Kingdom and the United Arab Emirates. The development of this global business benefits from the cooperation with global e-commerce platforms, including Amazon, Alibaba and AliExpress, enabling customers to easily purchase products. Since its establishment, Elego has also received extensive media coverage abroad, won many awards, and appeared in important publications such as Forbes, ZDNET and All3DP. Products are also frequently mentioned and emphasized by the industry's big V, including well-known YouTube channels such as UncleJessy, Tested and Thomas Sanderer. Undoubtedly, as a heavyweight product of Intelligent Technology, ELEGOO Jupiter carries the hopes and dreams of numerous researchers and designers, and is a "masterpiece" that gathers advanced manufacturing technology and innovative design concepts. Once launched, it was popular in the industry and became the focus of the industry.

This 6K resolution high-precision MSLA 3D printer has the following features:

Large volume and high precision: generally, the larger the print size of the light curing printer, the lower the pixel density, and the low resolution light source cannot achieve high precision printing. Jupiter is equipped with a 12.8-inch 6K LCD screen, which can obtain a large size and high-quality print model. With this machine, users will be able to print models up to 277.8mm x 156.0mm x 300mm.

All-metal structure: all modules and main parts of the fuselage are made of high-strength metal. The fuselage is made of sheet metal, which has high strength, aging resistance and is not easy to be scratched. The door handle and other parts are made of aluminum alloy shell, which makes the product more fashionable and light;

5.0-inch new touch capacitive screen: 5.0-inch high-definition capacitive screen, which is more convenient to watch and touch, simple to operate, without delay and stagnation during operation, easy human-computer interaction, supporting multiple different languages, and bringing a new user experience;

Automatic feeding: the feed chute is equipped with an automatic feeding port, which is attached with an automatic feeding bottle cap, and is installed in a built-in way to transport/supply resin at any time. There is no need to worry about the situation that the printing stops due to the use of resin during the printing process. (Based on the principle that the atmospheric pressure is equal inside and outside, when the amount of resin in the feed tank is not enough, the feed inlet will automatically supply resin to prevent printing from suddenly stopping.)

Ball screw: Z-axis adopts high-quality ball screw, which runs smoothly and is durable, and the whole printing process is quiet and noiseless (as low as 60 dB). The four-slider design makes its positioning accuracy higher, increases the printing success rate and facilitates ultra-high precision printing. Most importantly, its service life is longer than that of ordinary screw rod.

Odor control: Jupiter is equipped with a built-in mini air purifier. Activated carbon can absorb and filter the irritating resin odor, form internal circulation in the relatively closed space of the case during the printing process, and continuously filter the gas generated during the printing process, giving you a fresh and safe use experience. This is a very considerate design and is also a rare configuration in the light curing 3D printer.

Humanized design: the construction plate and material trough are equipped with handles and handles, and the handle on the side of the body is increased. Built-in lighting - control the use of lighting switch through touch screen, diffuse light source, ensure uniform and soft light, eliminate dark areas, more close to nature, more care for your eyes, led patch, long service life. Modular design - the shell, Mono screen and z-axis on the upper part of the machine's middle plate can be disassembled and assembled to facilitate the replacement of screen and other parts and subsequent DIY requirements. DIY expansion - Jupiter machine will open source hardware structure, and modular design allows users to conduct more interesting DIY exploration; At the same time, the government will continue to develop relevant expansion kits for consumers to choose from.

Fifth place: Creative 3D - Reality CR-6 SE

Crowdfunding: $4325342 (about 28.94 million yuan)

Number of supporters: 10401

CREATIVITY 3D is a 3D printer brand of Shenzhen CREATIVITY 3D Technology Co., Ltd., established in 2014, and is an emerging domestic 3D printer supplier focusing on overseas markets, with products covering "FDM and UV curing". CR-6 SE is their first crowdfunding 3D printer. It raised about 4.3 million dollars and more than 10000 supporters on Kickstarter as soon as it came out. The system is equipped with some ingenious innovations aimed at solving common problems commonly found in consumer-grade FDM printers.

In order to solve the old problem of bed surface leveling, the new machine provides a built-in "level-free device", which uses intelligent pressure sensors to continuously and automatically level the bed surface, so that users do not have to do this work. In December 2021, 3DQue, a developer of 3D printing automation technology in Vancouver, announced the launch of a matching new Quinly automation kit for CR-6 SE. This Quinly kit can activate the platform leveling system of the printer, as well as the filament run-out sensor of the printer, so that reliable multi-day printing operations do not require any manual user input. The software will even notify the operator when the thread is used up or the bed needs to be leveled for maintenance.

In addition, this machine can build 235 × two hundred and thirty-five × 250 mm volume, using modular nozzle design and STM32F103RET6 chipset's silent Trinamic controller and silent cooling fan, silicon carbide glass hotbed platform, double Z-axis design and weight of only 9.5 kg. The machine uses the Phtoelectric filtration sensor to ensure smooth printing, and a 4.3 inch high-definition color LCD touch screen. The machine costs 375 pounds (about 3274 yuan).

△ Creativity CR-6SE 3D printer. Photo from Creativity

Consumer-grade 3D printing, China occupies an absolute leading position

On September 8, 2021, as a professional 3D printing platform in China, the Antarctic Bear organized a consumer-level 3D printing "exchange dinner" in Shenzhen, which was supported by a group of global leading upstream and downstream manufacturers of the consumer-level 3D printer industry chain. Their total equipment shipments in 2020 were nearly 2 million.

▲ Enterprise representatives who participated in this consumer-level 3D printing exchange meeting have accounted for half of the global market, from left to right:

● Xiao Guoyue, General Manager of Shenzhen Yongchanghe (3D printing resin material)

● Ouyang Xin, co-founder and deputy general manager of ANYCUBIC (FDM/LCD/DLP 3D printer) in Shenzhen

● Liu Jianwen, General Manager of Shenzhen Pengji Optoelectronics (LCD screen/optical machine)

● Liu Huilin, co-founder and deputy general manager of Shenzhen Creative 3D Creativity (FDM/LCD 3D printer)

● Pei Wenjian, founder and general manager of Zhejiang Flash Casting Technology (FDM/LCD/DLP/wax spray 3D printer)

● Yang Yihu, founder and chairman of Shenzhen Guanghua Weiye eSUN Eason (FDM wire, 3D printing resin material)

● Li Haixiong, chief editor of Antarctic Bear 3D Printing Network

● Ouyang Lu, co-founder and general manager of ANYCUBIC (FDM/LCD/DLP 3D printer) in Shenzhen

● Chen Chun, co-founder and general manager of Shenzhen Creative 3D Creativity (FDM/LCD 3D printer)

● Li Zebin, founder and general manager of Shenzhen Atomstack (elastic material FDM 3D printer)

● Hong Yingsheng, founder and general manager of Shenzhen Intelligent Pielegoo (FDM/LCD 3D printer)

● Chen Xuedong, co-founder and general manager of Snapmaker (multi-function 3D printer) of Shenzhen Rapid Manufacturing Technology ● Qu Yuhui, co-founder of Zhejiang Flash Casting Technology (FDM/LCD/DLP/wax spray 3D printer)

After three rounds of wine inspection, many manufacturers reached a certain consensus in the above dinner:

1. We should insist on being a "3D printing preacher". For example, we will promote the further popularization of 3D printing technology and expand the whole market through joint competition and 3D printing into schools and other activities.

2. We should continue to invest in research and development, strengthen technological innovation, create greater value for users, enhance brand value, and break the industry insiders.

3. We should further expand the industrial application of 3D printing, and promote the rooting, flowering and results of 3D printing technology in all walks of life.

4. We should work together to develop product standardization. Pay attention to product certification, improve product quality and enhance the confidence of potential users in 3D printing technology.

5. We should strengthen product innovation and encourage harmony but difference.

6. In addition to normal market competition, manufacturers should also strengthen cooperation to jointly promote the healthy and healthy development of the 3D printing industry.

Now in June 2022, less than a year has passed, two consumer-grade 3D printing black horses, Shenzhen Anke Innovation and Shenzhen Tuozhu Technology, have emerged in China. They have gained international popularity through crowdfunding. The industry has changed too fast. The polar bear hopes that the manufacturers in the industry can unite in the competition and develop more healthily and sustainably together.

|

Prev:None!

Next:None! |

Return |